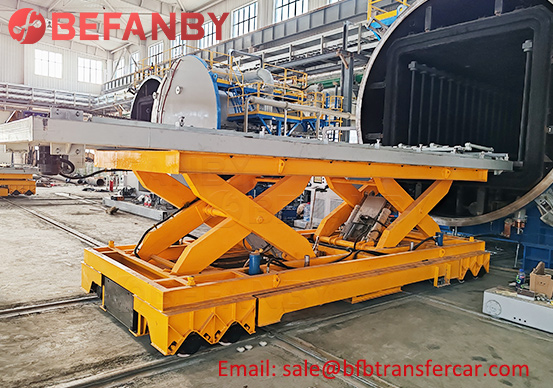

Battery Power Automated Rail Guided Vehicle With Hydraulic Lift System

Project Introduction

This project is 2 set Battery Power automated rail guided vehicles customized by us for customers, used to dock and transfer workpieces in different furnace bodies. Its main functions include automatic control, cross rail changing, lifting, etc. The specific working principle is that the automated rail guided vehicle is controlled by automated PLC, and both use two-speed (low speed, high speed) control. The positioning of the automated rail guided vehicle is relatively accurate and saves electricity. The automated rail guided vehicle is controlled manually and automatically through the central control system. In manual mode, the automated rail guided vehicle is manually controlled through the vehicle control handle or remote control reserved for the automated rail guided vehicle. (Control signals include forward, backward, hydraulic pressure increase, hydraulic pressure decrease, track change, etc.) The control signals are all controlled by inching. In the automatic mode, calls are made through the call system of each workstation. The call signal receives the call instruction through the wireless transmission system, and then the central control issues instructions to the automated rail guided vehicle in the waiting area. The automated rail guided vehicle automatically determines the workstation being called, and automatically Go to the called work station.

Technical Parameters

Model: KPX

Qty:2 Sets

Capacity: 5 Tons

Table Size: 5200*2150*800mm

Lifting Height:1115mm

Running Speed: 0-5m/min

Running Distance: 9m/20.7m

Operation: Hand Pendant + Remote Control + Touch Screen

Client Company Introduction

Our client company is a national-level specialized and innovative "little giant" enterprise. Relying on carbon-based material preparation technology and focusing on equipment manufacturing and process services, it has become a leading enterprise in the research and development and application of carbon-based material equipment. We are committed to the R&D, manufacturing and industrialization verification of high-purity graphite and carbon-based material equipment. We have established key core equipment R&D centers and production bases and related manufacturing process technology industrialization verification platforms. We can provide high-temperature purification equipment and gas phase equipment required for the preparation of carbon-based materials. Deposition equipment, graphitization equipment, continuous soft felt purification equipment and other core equipment and process technology integration services have the industrialized production verification production capacity of 100 tons of carbon-based composite materials per year and the R&D and manufacturing capacity of 50 sets of equipment. The product quality is at the The industry's advanced level provides a typical example for the localization of high-end carbon-based material equipment and its complete line delivery.

Advantages Of Automated Rail Guided Vehicle:

1. Flexibility: This automated rail guided vehicle can automatically lift and lower to adapt to different working scenarios. It can be lifted and lowered at different heights to adapt to objects of different heights and operational needs.

2. Efficiency: The automatic rail changing function allows the car to move on different tracks, thereby quickly switching between multiple work areas and improving work efficiency.

3. Safety: automated rail guided vehicle can operate in many environments, especially hazardous environments. Through automatic rail changing and lifting functions, the automated rail guided vehicle can avoid the risks of manual operation and ensure the safety of workers.

4. Accuracy: Since the lifting and movement of the automated rail guided vehicle is carried out through a precise control system, its accuracy can be ensured. This kind of precision is necessary in many industrial applications, such as in manufacturing, production lines, assembly lines, etc.

5. Save manpower: Using an automated car can save manpower because it can complete many tasks automatically without manual operation. This allows companies to reduce labor costs and increase production efficiency.

6. Reliability: The automated rail guided vehicle has a high degree of reliability because it is composed of a sophisticated control system and advanced hardware. It can work continuously for a long time and can operate in harsh environmental conditions.

Automated Rail Guided Vehicles Video

BEFANBY Company Advantage

BEFANBY is a designer and manufacturer dedicated to global material handling solutions. With more than 20 years of production and design experience, it is the earliest handling equipment manufacturer in China. It is also the leader in the handling equipment industry and the only one in the industry. A specialized and innovative enterprise. Currently, we can customize and produce various types of handling equipment, including hundreds of types of handling equipment such as intelligent heavy-duty AGVs, automated rail guided vehicles, rail transfer cars, trackless transfer carts, flatbed trailers, turntables, etc. The company has CE, SGS, ISO9001 and other certifications, has more than 70 patents, and exports to more than 90 countries.

Welcome to contact us to get your handling solutions.