The Difference Between Rgv Rail Transfer Cart And Agv

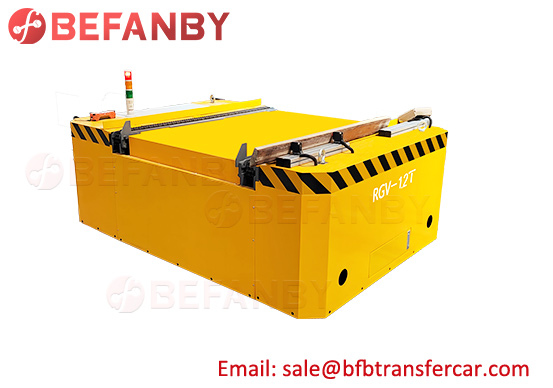

RGV rail transfer cart and AGV automated guided vehicle, all are our mature material handling equipment manufactured by BEFANBY. And many project are designed. Now we will introduce the main difference between rgv rail transfer cart and AGV.

In the field of modern logistics and production, the application of automation equipment is becoming more and more common. With the development of technology, rail guided vehicles (rgv) and automatic guided vehicles (AGV) have become two common types of automation equipment. Although they are both used for logistics and transportation, there are some clear differences in design, function and application. This article will introduce the difference between rgv rail transfer cart and AGV automatic guided vehicle in detail.

First of all, rgv rail transfer cart is an automated equipment that navigates and moves through rails. In contrast, the AGV automatic guided vehicle is a navigation system that does not need to rely on rails. This is one of their most notable differences.

In terms of design, rgv rail transfer carts usually require a fixed layout and setup at the workplace. The rails are necessary so that the rgv can move along a fixed track. In contrast, AGVs do not require specific layouts and setups. They rely on advanced navigation technology, such as laser navigation or vision navigation, to move freely in different workplaces. This makes the AGV more flexible in its ability to adapt to different environments and tasks.

In terms of function, rgv rail transfer carts are usually used to transport items on a fixed path. They are often used for logistics transportation on the factory production line to ensure that items arrive at the designated location according to the predetermined route and time. On the other hand, the AGV automatic guided vehicle is more flexible and can make path adjustments and task changes as needed. They can make autonomous decisions and avoid obstacles through preset programs to adapt to the frequently changing logistics environment.

In addition, rgv railcars require fixed line planning and installation. Rail systems often require complex wiring and adjustments before use. However, AGVs do not require this cumbersome installation process, they can be used immediately and adjusted at any time. This makes AGV more advantageous in terms of cost and time efficiency.

In terms of application, rgv rail transfer carts are mainly used for logistics transportation of large-scale factories and production lines. Thanks to their fixed paths and high efficiency, they enable accurate and fast handling and distribution of items. In contrast, AGV automatic guided vehicles can be widely used in various environments and needs. Whether it is warehousing, medical care, logistics sorting or electronic equipment production, AGV can flexibly adapt and provide efficient automated transportation solutions.

To sum up, rgv rail vehicles and AGV automatic guided vehicles are two different types of automation equipment. They differ significantly in design, function and application. RGV relies on rail navigation and is more suitable for logistics transportation with fixed paths; while AGV realizes free and flexible movement through advanced navigation technology and adapts to various logistics environments. Choosing the right automation equipment depends on specific needs and workplace conditions.

BEFANBY can customized different type material handling equipment on demand, welcome to contact us to get your handling solution.

Video of AGV and RGV